Boiler & Their Types

Boiler Overview:

A boiler is a closed vessel in which fluid (usually water) is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications. Boilers can be classified based on their design, fuel type, pressure, and application. They are widely used in industries, power plants, and residential heating systems.

Fire Tube Boiler:

A fire tube boiler is one of the oldest types of boilers. It consists of a shell containing water and steam, with a series of tubes running through it. The fire tube boiler operates by passing hot gases through the tubes, which are immersed in water. The heat from the gases is transferred to the water through the walls of the tubes, generating steam.

Here's a detailed explanation:

Components:

- Shell: The outer cylindrical vessel that contains water and steam.

- Fire Tubes: These are the tubes through which hot gases from the combustion chamber pass. They are surrounded by water and are responsible for transferring heat to the water.

- Combustion Chamber: It is where the fuel (such as coal, wood, or oil) is burned, generating hot gases.

- Smokebox: This is where the exhaust gases exit the boiler after passing through the fire tubes.

Operation:

- Fuel is fed into the combustion chamber, where it is burned to produce hot gases.

- The hot gases flow through the fire tubes, heating the surrounding water.

- Heat is transferred from the hot gases to the water, generating steam.

- The steam rises to the top of the boiler shell and is collected for use in various applications.

- The cooled exhaust gases exit the boiler through the smokebox and are expelled into the atmosphere.

Advantages:

- Simple design and easy maintenance.

- Suitable for small-scale applications.

- Quick steam generation.

Disadvantages:

- Limited steam generation capacity.

- Prone to explosions if water level drops below the fire tubes.

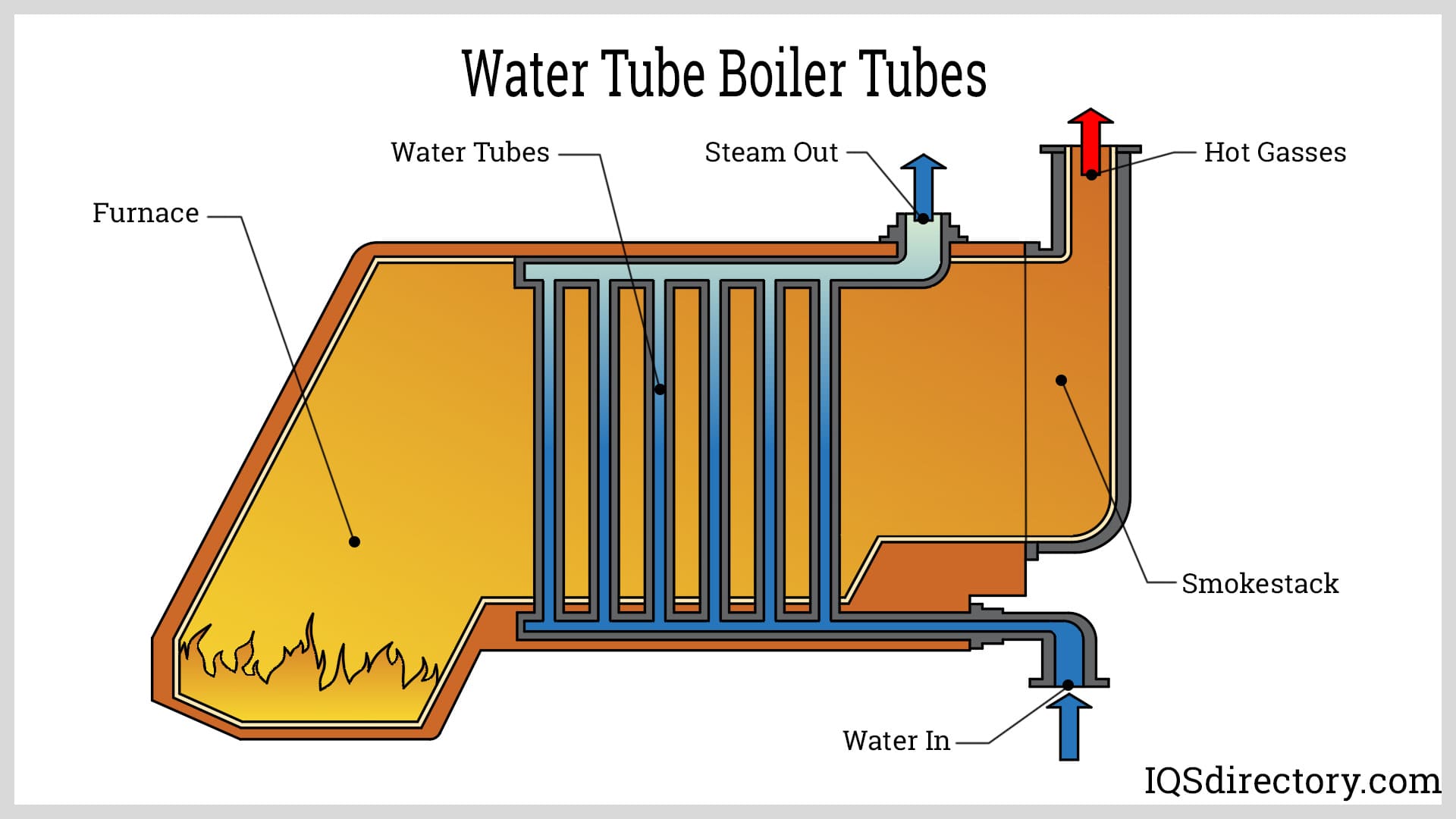

Water Tube Boiler:

In contrast to fire tube boilers, water tube boilers have the water flowing inside the tubes while hot gases flow outside the tubes. They are more complex in design but offer several advantages.

Here's a detailed explanation:

Components:

- Steam Drum: A large cylindrical vessel where steam is collected before being distributed.

- Water Tubes: These are small diameter tubes arranged in a specific pattern inside the boiler. Water flows through these tubes.

- Downcomers: These are pipes that carry water from the steam drum to the water tubes.

- Headers: They are used to distribute water or steam to the different sections of the boiler.

- Superheater: A section of the boiler where steam is heated to a higher temperature to increase its energy content.

- Economizer: A heat exchanger that preheats the feedwater before it enters the boiler.

Operation:

- Water is pumped into the boiler and distributed to the water tubes through the headers.

- The water is heated by the hot gases flowing outside the tubes, converting it into steam.

- The steam rises to the steam drum, where it is collected and then distributed for use.

- Some water may be converted into steam in the superheater, increasing its temperature and energy content.

- The cooled exhaust gases exit the boiler through the chimney.

Advantages:

- Higher steam generation capacity.

- Faster response to load changes.

- More efficient heat transfer.

Disadvantages:

- Complex design and construction.

- Higher initial cost and maintenance requirements.

In summary, both fire tube and water tube boilers serve the purpose of generating steam, but they differ in their design, operation, and applications. Fire tube boilers are simpler and suitable for small-scale applications, while water tube boilers are more complex but offer higher steam generation capacity and efficiency. The choice between the two depends on factors such as steam requirements, space constraints, and operational efficiency.

Comments

Post a Comment