Mechanical cycle of refrigeration

Introduction:

The mechanical cycle of refrigeration is the foundation of modern refrigeration and air conditioning systems. It utilizes the principles of thermodynamics and the behavior of refrigerants to transfer heat from a low-temperature environment to a high-temperature one, thereby cooling the former and warming the latter.

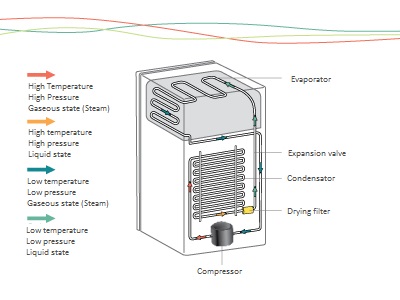

Components of the mechanical Cycle:

Compressor:

- The compressor is the heart of the refrigeration system. It is typically powered by an electric motor and is responsible for compressing the refrigerant gas, increasing its pressure and temperature.

- As the refrigerant moves through the compressor, its volume decreases while its pressure and temperature increase significantly.

Condenser:

- The high-pressure, high-temperature refrigerant gas then moves to the condenser, where it releases heat to the surrounding environment.

- In most systems, the condenser is a coil or series of coils with fins to enhance heat transfer. Air or water is commonly used to remove the heat from the refrigerant.

Expansion Valve or Capillary Tube:

- After the refrigerant has been condensed, it passes through an expansion valve or capillary tube, which reduces its pressure and temperature.

- This sudden drop in pressure causes the refrigerant to evaporate and absorb heat from its surroundings.

Evaporator:

- The low-pressure, low-temperature refrigerant vapor now enters the evaporator, where it absorbs heat from the space or substance being cooled.

- Similar to the condenser, the evaporator typically consists of coils or tubes through which the refrigerant flows. Air or another substance passes over these coils, transferring heat to the refrigerant and causing it to vaporize.

Working Principle: The mechanical cycle of refrigeration follows these basic steps:

- The compressor compresses the low-pressure refrigerant vapor, raising its temperature and pressure.

- The hot, high-pressure refrigerant then flows to the condenser, where it releases heat to the surroundings and condenses into a liquid.

- From the condenser, the high-pressure liquid refrigerant moves through the expansion valve or capillary tube, where its pressure drops suddenly, leading to a decrease in temperature and the formation of a mixture of liquid and vapor.

- This cool, low-pressure refrigerant then enters the evaporator, where it absorbs heat from the space being cooled, causing it to vaporize completely.

- The cycle repeats as the low-pressure vapor returns to the compressor to be compressed again.

Types of Refrigeration Systems: There are various types of refrigeration systems based on the mechanical cycle, including:

- Vapor Compression Refrigeration System: The most common type, as described above.

- Absorption Refrigeration System: Uses a heat source, such as natural gas or waste heat, to drive the refrigeration cycle instead of a compressor.

Applications: The electrical cycle of refrigeration is used in various applications, including:

- Domestic refrigerators and freezers

- Commercial refrigeration systems (e.g., walk-in coolers, refrigerated display cases)

- Air conditioning systems for residential, commercial, and industrial buildings

- Refrigerated transportation (e.g., trucks, ships, airplanes)

- Industrial processes requiring cooling or temperature control

Conclusion: The mechanical cycle of refrigeration is a fundamental process used to create and maintain low temperatures in various applications. By understanding the principles behind this cycle and the components involved, engineers can design efficient and reliable refrigeration and air conditioning systems to meet a wide range of cooling needs.

Arigato❣️

ReplyDelete